Before I get going on this one I’m issuing a disclaimer: this story will be presented in a Choose Your Own Adventure-style format. There’s a fairly important thing I ran…

I like asking people “what’s the last good book you read?” I just finished Neil Strauss’ “The Game“, an autobiographical account of the author’s foray into the world of pickup…

2013, here we go. Technically this dish falls in the Autumn menu for Alinea, but last year I didn’t get to make it through as many fall dishes as I’d…

In continuing with my little sidecar Bitters adventure I’ve been on: I recently participated with some friends in a craft fair; these friends and I have each been experimenting with…

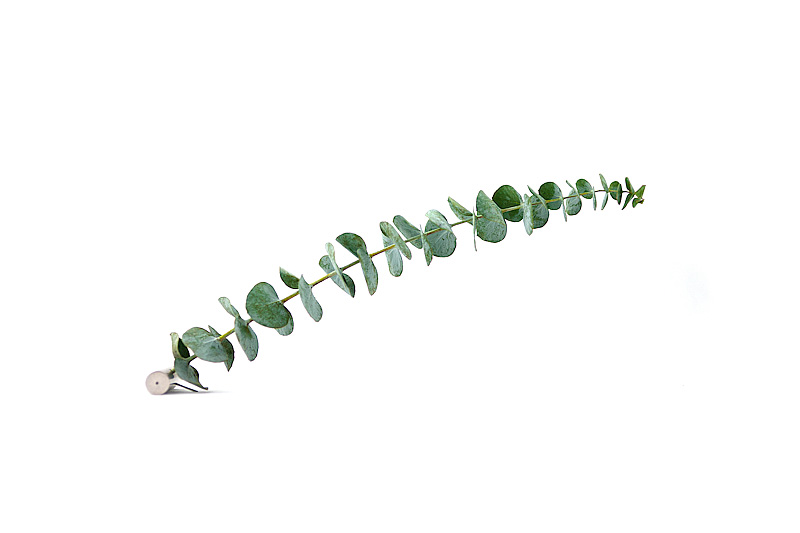

Smoked salmon mousse, lemon-saffron pudding, herb powder, flakes of smoked salmon filet, garlic chips, logs of salsify rolled in olive oil mayonnaise and a powder of smoked salmon, caper, red…

A couple weeks ago, Sarah and I did a bit of traveling overseas. The day before we left, Sarah called me to let me know she was standing in front…

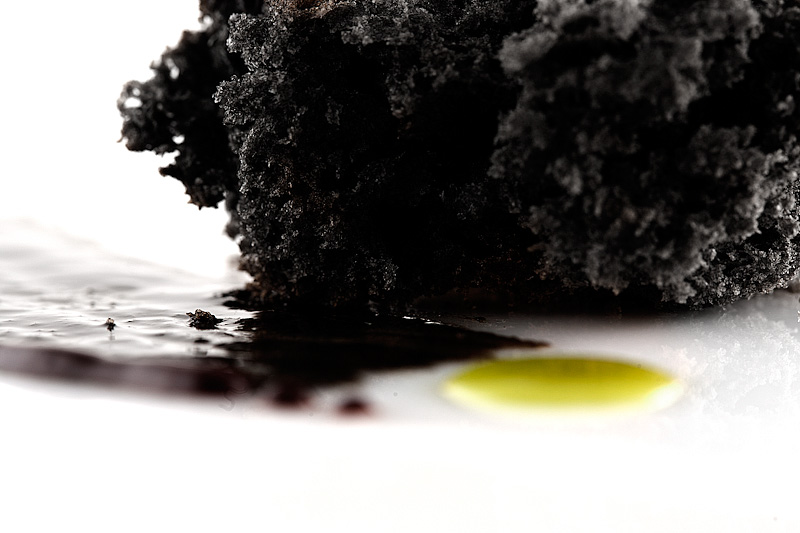

Friday night I was flipping through a friend’s copy of Natura, a collection of desserts from El Bulli by Ferran Adria’s brother, Albert. I came across a section detailing some…

Though I wrote a few days ago about this past weekend’s cooking adventure, I still have some residual thoughts rolling around my head about it. I tried to be ok…

In the documentary “It Might Get Loud”, Jack White says this peculiar thing about how when he’s playing at a concert, if he’s meant to move from the guitar to…

Whole lotta stuff happening all at once here lately; we’re two weeks away from wrapping work on the project I’m on at work currently so the hours are a little…

I feel like I’m moving a little sluggishly here lately; work remains intense and will be for another month or so, and the shift in seasons carries with it a…

This is a slight non-sequitur, but as a followup to my bitters experiments a few weeks back: Cooking Issues has an article on their (awesome) blog about rapid infusion using…

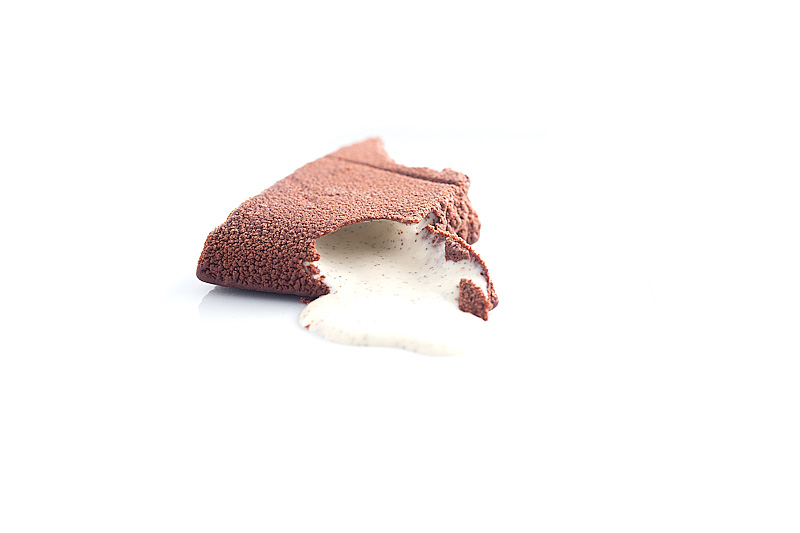

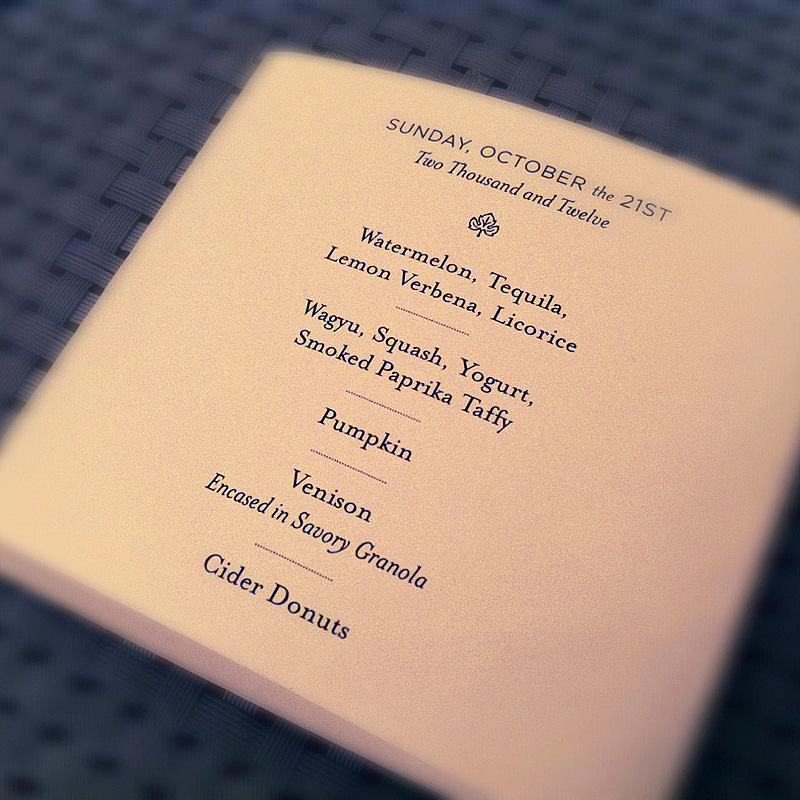

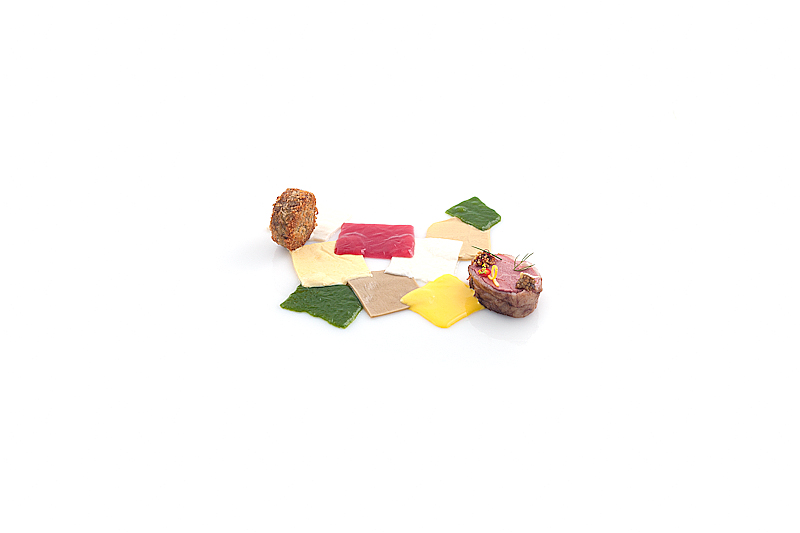

Mignardises (literally, “sweets”) are small, final bites served at the end of a meal that are meant to serve as one last token of gratitude/farewell from the Chef; they are tiny sweet…

Last weekend, Sarah took the 3-day weekend to travel to visit her brother. Knowing I had a long weekend to myself, I started sifting through the cookbook to figure out…

This weekend is my birthday. Yesterday, some friends and I went to do my favorite thing in the Bay Area: drive an hour north to Tomales Bay to eat fresh raw…

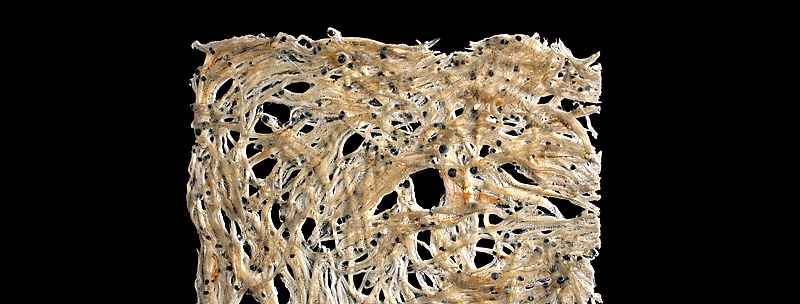

A digression, if I may. I bought the Mugaritz cookbook on the recommendation of a friend several weeks ago. It’s sort of blowing my mind; it’s a little like an…

Work’s gotten a little overwhelmingly busy for me lately, and it’s sidelined the time I have to spend in the kitchen. I get itchy each time this happens, but this…

So, I’ve never tasted porcini mushrooms. I’m kinda bad at mushrooms in general; growing up, ‘mushrooms’ were either of the canned variety (!) or–for special rare occasions–took the form of…